SUIVEZ-NOUS:

-

Hangzhou, China

Custom Membrane Keypad Manufacturer

Membrane Keypad Manufacturer

Membrane keypad switches are indispensable in a variety of electronic devices, offering a lightweight, compact, and economical solution for user input. This article meticulously details the manufacturing process of membrane keypads switches, from the initial design and development phase to production, assembly, and quality assurance. The aim is to ensure a thorough understanding of this intricate process.

Membrane Keypad Prototyping

- Prototype Design: The journey begins with the design of the membrane keypad switch. Designers craft the graphical interface, while engineers leverage their extensive experience to work on the circuit, structure, and molds (including embossing and die-cutting molds). To delve deeper into membrane switch design, refer to the “Membrane Switch Design Guide.”

- Process Compilation: At this stage, engineers meticulously plan out the manufacturing workflow, detailing the required materials, equipment, steps, and quality control measures to guarantee a smooth production process. Regarding materials, you can read “Adhesive Solutions and Selection Guide for Double-sided Tapes in Membrane Switches” and “Membrane Materials Usage Guide for Membrane Switches & Capacitive Touch Switches” to learn more about the materials information for membrane switches.

Membrane Keypad Switch Production Preparation

- Material Cutting: Following the specifications in the process documents, the film materials and double-sided adhesive are cut according to the print layout dimensions and material types required.

- Plate Making: The printing film, once designed, undergoes a process to expose the pattern onto the silkscreen printing plate – a critical step for ensuring print quality.

Membrane Keypad Switch Official Production

Graphic Overlay Printing:

- Screen Printing: Utilizing the prepared silkscreen plate, graphics are transferred onto the film material.

- Digital Printing: For graphics requiring finer details or gradient colors, digital printing technology is the method of choice. You can read the article ‘Graphic Overlays and Membrane Switch Panels: Selecting the Optimal Printing Technology‘ about graphic overlay printing.

Circuit Printing:

Conductive ink is applied to print the circuit onto the specified area of the film, utilizing screen printing technology.

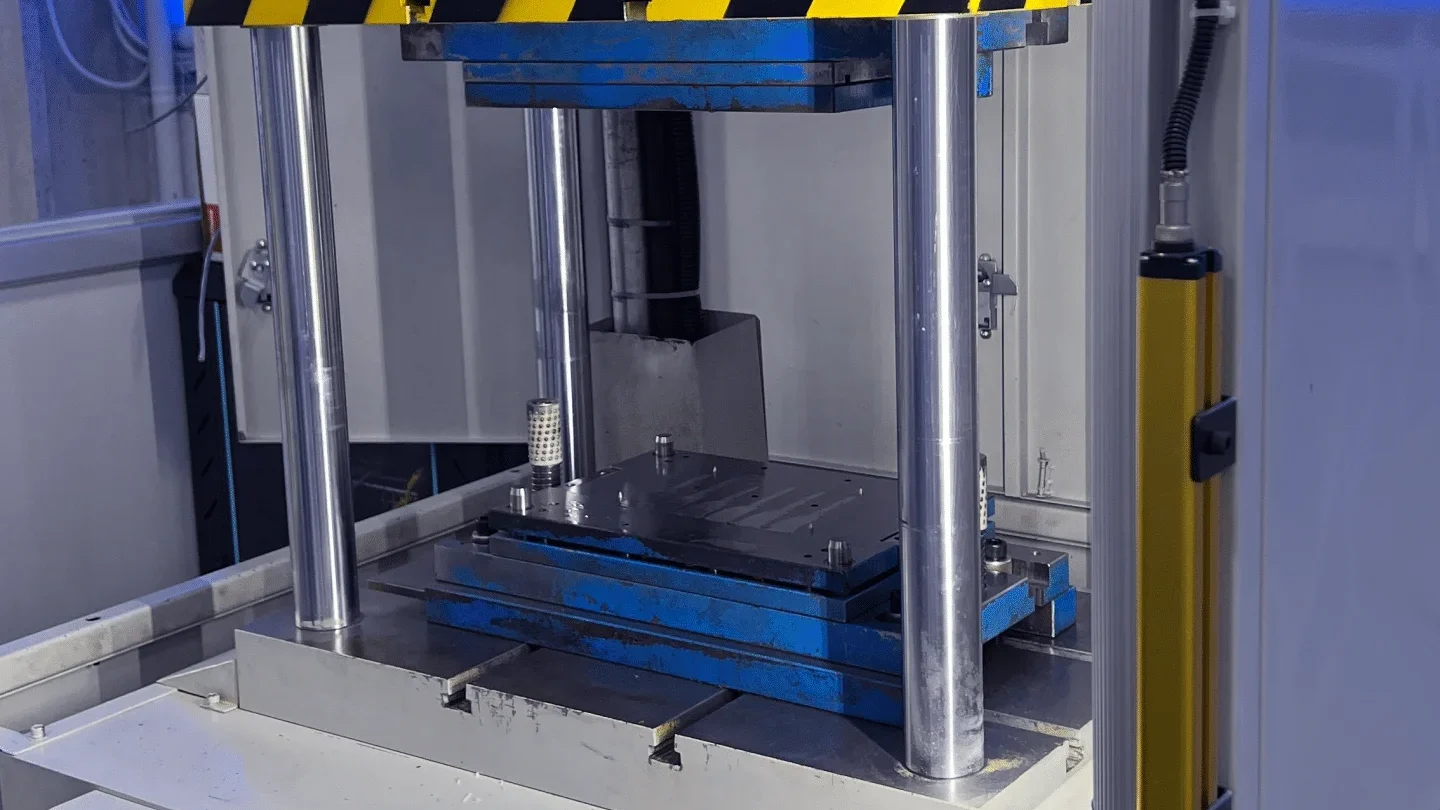

Machining:

- Panel Embossing: Employing a specially designed mold, raised buttons are created on the film. For a comprehensive guide on button embossing, see “From Membrane Switches to Graphic Overlays: The Selection and Application of Embossed Keys.”

- Component Die-Cutting: The printed film materials and double-sided adhesive undergo cutting and stamping using a die-cutting mold, creating the required components.

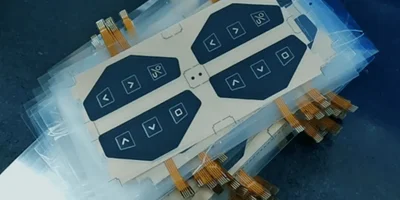

Assembly:

All the printed and machined film components, along with layers of double-sided adhesive, are assembled to form the complete membrane keypads switch.

Form Contour Die-Cutting:

The entire assembled membrane keypads switch is cut into its final product shape using a die-cutting mold.

Installing Connectors:

Metal terminals are secured at the end of the membrane keypads switch circuit through a riveting process, readying the switch for various types of connector installations. For additional information on connectors, refer to “What are the options for Membrane Switch Connectors?”

Inspection:

A comprehensive quality inspection is conducted based on the process documents from the engineering department and the SIP from the quality department, ensuring the product meets all design and performance criteria. You can read the article ‘To produce high-quality membrane switches, what inspections are required?‘ to learn more about the inspections for products such as membrane keyboard switches, capacitive switches, etc.

For the past and present of membrane switch keyboards read this article: What is a membrane switch? How do membrane switches work?

To learn more about membrane switches click here. We offer you services from prototyping to manufacturing.