FLLOW US:

-

Hangzhou, China

How to Select the Best Key Embossing Technology for Membrane Switches and Graphic Overlays

Membrane switches, as a human-machine interface, play an important role. Among them, the design of key embossing is a key technology that helps to enhance the user experience and enhance product usability. Next, we will introduce how to choose different types of embossing technologies according to needs.

Membrane switch key embossing is typically accomplished using a pair of molds—a male and a female mold—along with a heat press. In this process, the graphic overlay film or circuit film is placed between the male and female molds. The heat press heats these molds, and its heated platen is also brought to a specific temperature. Then, a specific pressure is applied, causing the male and female molds to interact and apply pressure to the film material. This combination of heat and pressure allows the film to form a raised shape under the influence of the molds. This method precisely controls the depth and shape of the embossing, ensuring that the keys provide good tactile feedback and operational response, while also enhancing the aesthetic and functional aspects of the membrane switch.

Because embossing makes the key area protrude from other parts of the panel, it is also used as a guiding information to help users find and identify the keys faster, letting users know they have successfully activated the keys.

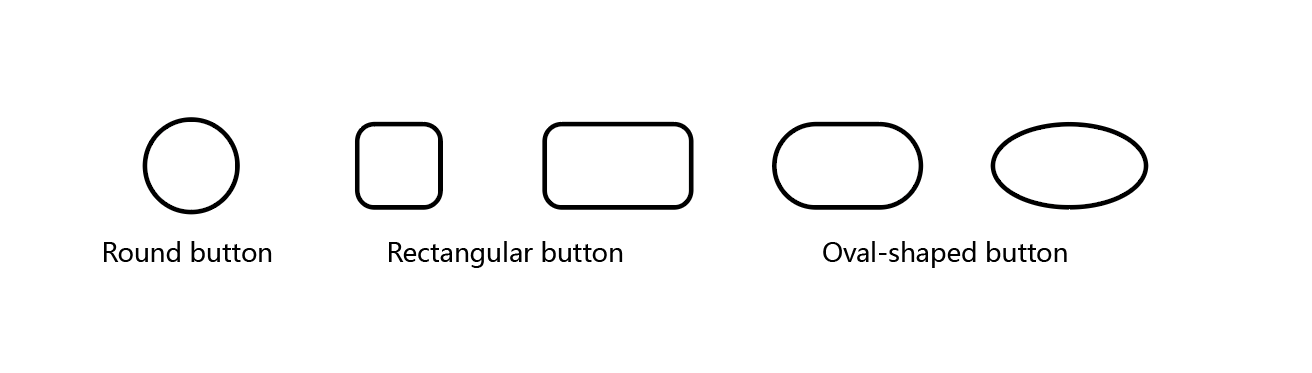

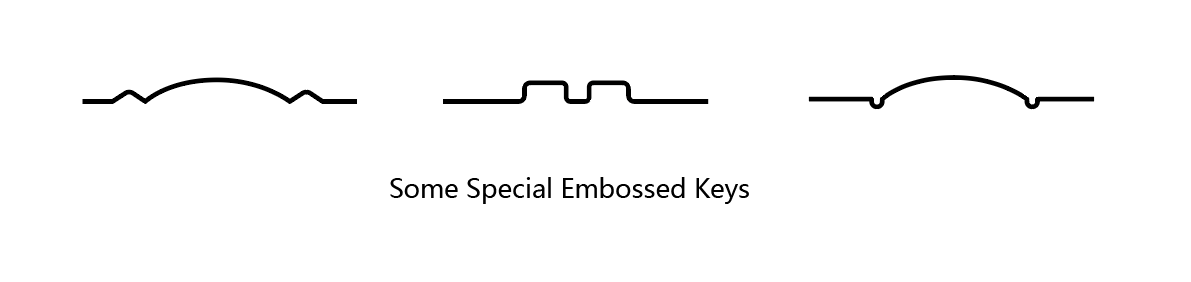

The key embossing of the membrane switch usually has the following types:

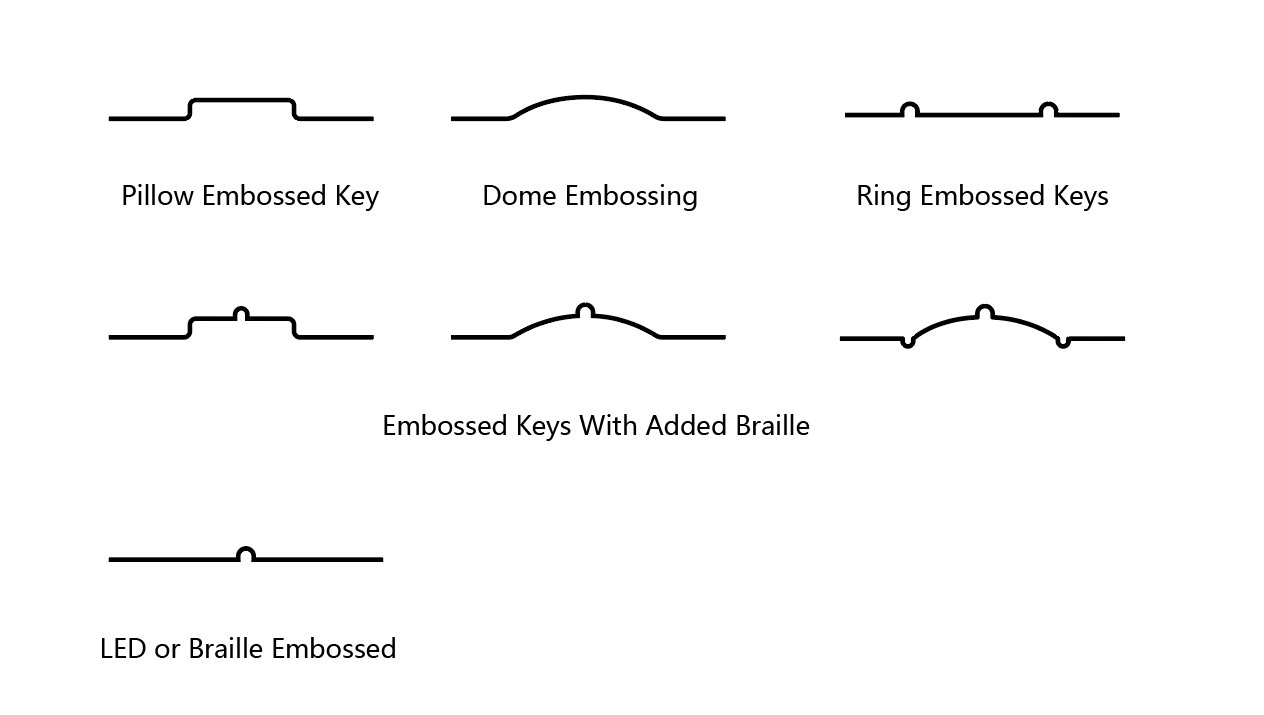

Pillow Embossed Key is suitable for keys of various shapes and can clearly indicate the button position.

Dome Embossing can provide a very good tactile feedback, but it can only be used for round keys.

Rim Embossed Key, only embossing the key or shape outline or edge, like the Pillow Embossed Key, it is applicable to most key shapes.

Braille Embossing can help visually impaired users identify and operate the device, it can be independently designed or used in combination with other types of embossing.

LED Embossing can make the embedded LED more conspicuous and provide an option for installing larger LEDs.