フォローしてください:

Adhesive Solutions and Selection Guide for Double-sided Tapes in Membrane Switches

Double-sided tape plays a pivotal role in membrane switches. This adhesive is created by coating acrylic adhesive onto various substrates. Its primary purpose is to bond different components, and its importance cannot be overstated. We will detail the types of double-sided tapes used in membrane switches from the following three perspectives。

- Types of Adhesives:

- Non-woven substrate tape: This type of tape is known for its excellent breathability and flexibility, making it suitable for applications that require a soft touch. Its thickness typically lies between 0.1-0.13mm, examples being 3M 9448A and 3M9075. The long-term temperature range is between 60-85°C.

- PET substrate tape: PET-based tapes are renowned for their superior high-temperature and chemical resistance. Their thickness usually varies between 0.15-0.3mm, an example being 3M9495LE. The temperature range typically lies between -40-200°C.

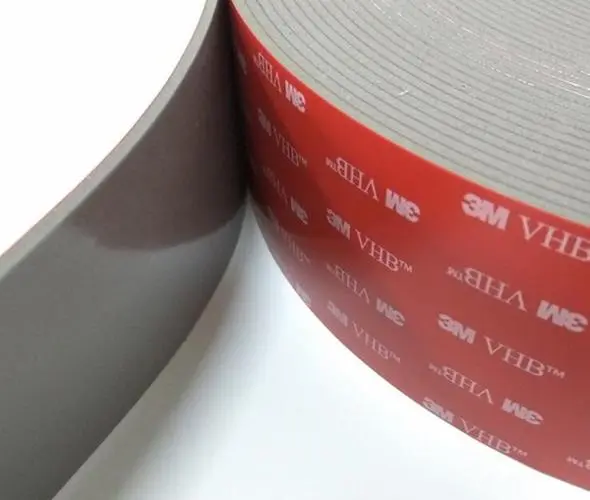

- Foam tape: This tape offers commendable cushioning and shock absorption, making it a go-to choice for applications that require impact absorption. Its thickness generally ranges from 0.2-1mm, like the 3M VHB series, with a temperature range of -40-90°C.

- Tape without substrate: This tape provides an ultra-thin bonding layer, making it ideal for applications that require a very thin bonding solution. Its thickness typically lies between 0.05-0.12mm, with examples being 3M467 or 3M468 pressure-sensitive adhesive. The temperature range is usually between -40-150°C.

Membrane Switch Structure and Application of Double-sided Tape:

- Spacer tape: The primary function of spacer tape is to separate different layers of the membrane switch. Polyester-based double-sided tape, like 3M9495, and PE foam-based tape, such as the 3M VHB series, are both adept at providing effective sealing, dustproofing, waterproofing, and aging prevention. Notably, PE foam tape is also used in the spacer layer of backlight membrane switches to block light, ensuring uniform backlight distribution.

- Backing tape: Backing tape is the essential component for adhering the membrane switch to the product. For applications with rough surfaces, tapes without substrates, like 3M467 or 3M468 pressure-sensitive adhesive, are typically chosen to ensure robust and stable adhesion.

Click here to understand the structure of membrane switches!

Brands of Double-sided Tape:

- American 3M: 3M is a frontrunner in the double-sided tape industry, offering a plethora of high-performance double-sided tape products catering to diverse application needs.

- German Tesa: Tesa is another prominent double-sided tape manufacturer, celebrated for its high-quality and trustworthy products.

- Japanese Brands: Including Comprehensive Research, Sekisui, Nitto, Direi Union, Teragaki, and more. These brands enjoy significant recognition in the Japanese and Asian markets, offering a range of specialized double-sided tape products.

In conclusion, selecting the appropriate double-sided tape is paramount for the performance and lifespan of membrane switches. Different applications and environments might necessitate different tapes. For instance, challenging conditions like humid environments and prolonged sun exposure set distinct requirements for the choice of double-sided tape. Therefore, when making a selection, it’s vital to consider all relevant factors thoroughly and seek expert advice.