FLLOW US:

-

Hangzhou, China

What is a membrane switch? How do membrane switches work?

What is a membrane switch?

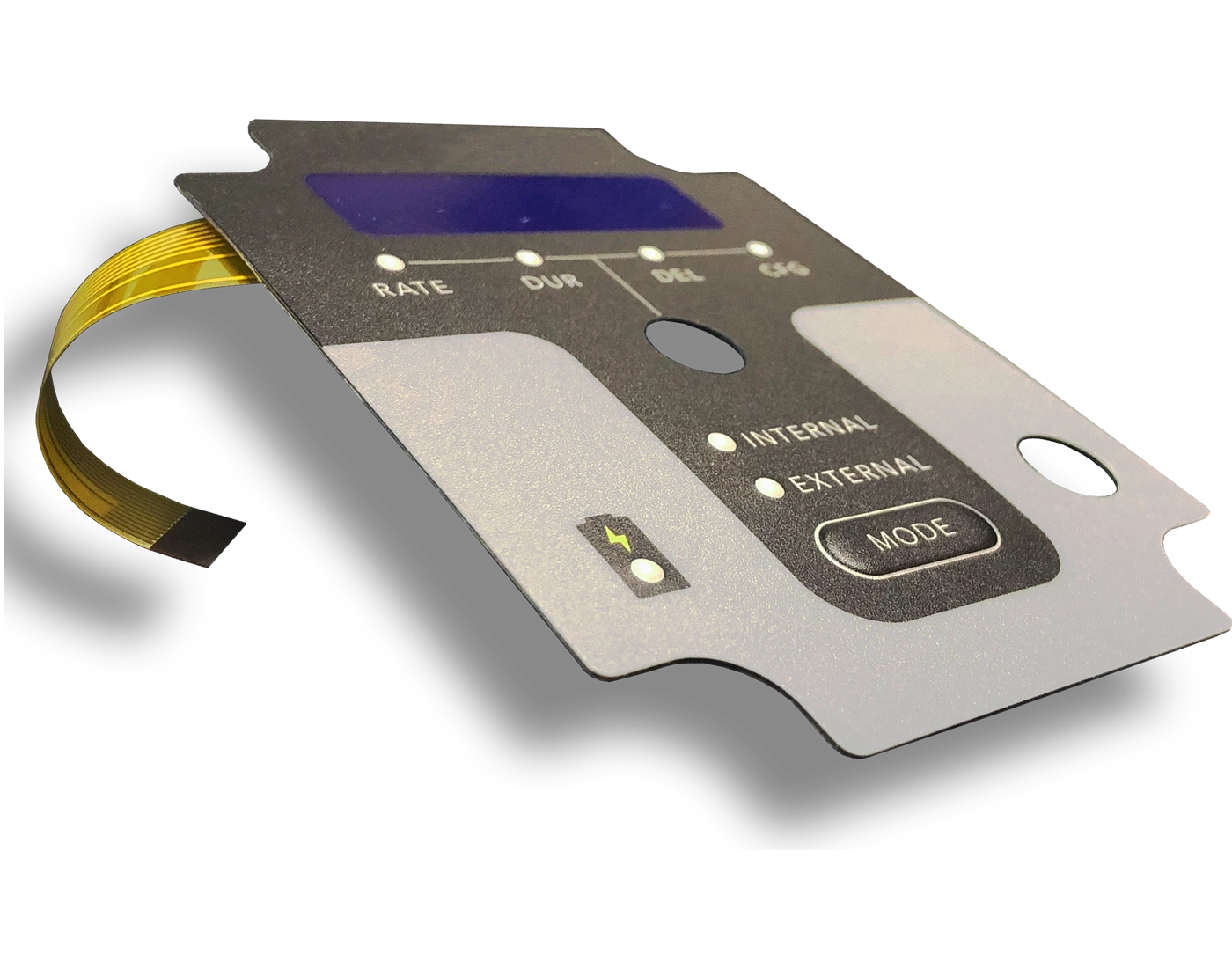

Membrane switches are not just electronic components; they are also a precision interface technology. In the construction of their multi-layer structure, each layer plays a distinct and important role. The top layer, the graphic overlay, is usually made of durable polyester or polycarbonate material, printed with exquisite icons and text. It not only provides intuitive operation guidance for users but also protects the inner circuits from external damage.

Below the overlay layer, there are one or several layers of conductive printed circuits. Manufacturers use conductive inks made from silver, carbon, or other materials to print precise circuit patterns on thin and flexible substrates. This layer is crucial to the switch’s functionality; the position of the keys corresponds to specific circuit designs to ensure that commands are accurately transmitted when the user performs an action.

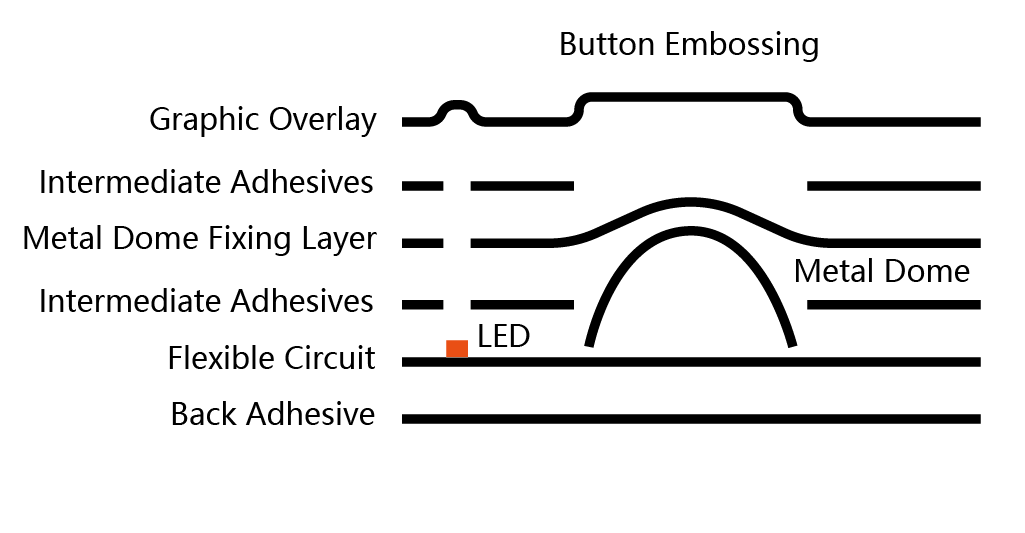

Some designs of membrane switches also include a layer of metal domes, which not only provide physical feedback, the familiar “click” sensation but also help to restore the graphic overlay to its original position, ensuring the switch can withstand tens of thousands of activations.

How does it work?

Membrane switches are electronic switches that are set or printed on a layer of membrane; they typically consist of several thin and flexible layers of film materials. When a user presses on the front panel of a membrane switch, it causes the conductive layers below to make contact, thereby completing the circuit and generating a signal. When the pressure is released, the conductive layers separate, interrupting the circuit and stopping the signal.

The History of Membrane Switches

Early History

- 1950s: During this period, early explorations were made into the control interfaces for electronic devices, focusing mainly on mechanical buttons and switches. The beginnings of membrane technology likely stemmed from simple circuits found in early laboratory and industrial equipment.

- 1960s: Technological advances in plastics and film materials made the concept of membrane switches viable. Engineers designed the first-generation membrane switches, typically composed of multiple layers of plastic and conductive materials to perform simple on/off functions. These switches gained popularity due to their lightness, durability, and cost-effectiveness.

Technological Development

- 1970s: The membrane switches of this era started incorporating more complex designs with multi-layer structures, including conductive traces and contact points. They found their place in devices like calculators, remote controls, and the early household electronics, starting to replace traditional mechanical switches.

- 1980s: The widespread adoption of personal computers and video games created a high demand for reliable, high-performance user interfaces. This led to further advancements in membrane switch technology. During this time, they were used for keys and began to create more complex interfaces, such as keyboards and game controllers. This period also saw the inception of touchscreen technology, providing a foundation for integrating membrane switches into more sophisticated interactive systems.

- 1990s: As technology matured, membrane switches achieved greater precision and complexity in their functions. This included touch pressure sensitivity, integrated LED backlighting, and complex graphic interfaces. Membrane switches became extensively used in automotive control panels, portable devices, and medical equipment.

Modern Membrane Switches

- Early 21st Century: Membrane switches of this period could provide haptic feedback and were designed for enhanced user-friendliness and ease of use. They were increasingly integrated into various daily use devices, including home appliance control panels and industrial control systems.

- 2020s: The popularity of smartphones and tablets saw membrane switch technology becoming a critical component of touchscreen technology. They needed to be not only sensitive and precise but also durable enough to handle tens of thousands of repeated touches while maintaining reliability over the long term.

Advantages of Membrane Switches

- Durability and Reliability: Membrane switches are crafted using wear-resistant materials like polyester, ensuring longevity under repetitive use. These switches can resist scratches and abrasions, maintaining stable performance even under extreme temperatures and harsh conditions. Furthermore, they can withstand prolonged mechanical interactions without damage, preserving consistent touch and feedback, which is vital for applications requiring frequent use.

- Cleanliness and Hygiene: The surface of a membrane switch is smooth and can be completely sealed, making them exceptionally easy to clean. This feature is crucial for medical devices and food processing equipment that must maintain sterile or sanitary conditions.

- Sealing Properties: Excellent sealing prevents the ingress of moisture, grease, dust, and even chemicals. This seal is achieved using adhesives and sealing materials between the layers of the switch, which is critical for devices that may be exposed to damp or dusty environments.

- Design Flexibility and Customization: Membrane switches offer high customization, including aesthetic design (color, graphics, size, and shape) and electrical characteristics (circuit design and conductive ink layout). This customization extends beyond physical shape to tactile feedback and integrated electronic components such as LEDs, resistors, and capacitors, forming a unified control system. In specific applications, like medical devices, membrane switches can be designed with antimicrobial surfaces.

- Compact and Space Efficiency: The compact design of membrane switches allows them to be integrated into applications where space is at a premium, thereby freeing up room for additional features or simplifying the overall product design.

- Cost-Effectiveness: Membrane switches are more economical in terms of production costs compared to traditional mechanical switches. The manufacturing process is streamlined with less material consumption and can be highly automated. Their long-term durability reduces the need for maintenance or replacement, further lowering the total cost of ownership.

Learn more about WeGlow products.

Manufacturing Process of Membrane Switches

The manufacturing process of membrane switches is a precise and multi-step operation, generally comprising the following main steps:

- Design: Establish customer requirements, and design the circuit and appearance. For more information on membrane switch design you can visit the article ” Membrane Switch Design Guide “.

- Printing: Print conductive ink on a substrate to form the circuit.

- Lamination: Combine different layers (such as the spacer layer, tactile layer, and graphic layer) together.

- Cutting: Cut the membrane switch to the required size and shape.

- Testing: Conduct tests for electrical functionality and mechanical durability.

For more detailed information on the membrane switch manufacturing process, you can visit the article “Membrane Keypad Switch Manufacturer’s Production Process”

Construction of Membrane Switches

- Graphic Overlay

- Function: The graphic overlay is the top layer of a membrane switch, providing visual indications for the user such as button positions, indicator signs, or branding.

- Materials: Common materials include Polyester (PET) and Polycarbonate (PC) which offer good durability and clarity.

- Customization: This layer can be customized with a variety of colors and patterns using screen printing, digital printing, or UV printing techniques.

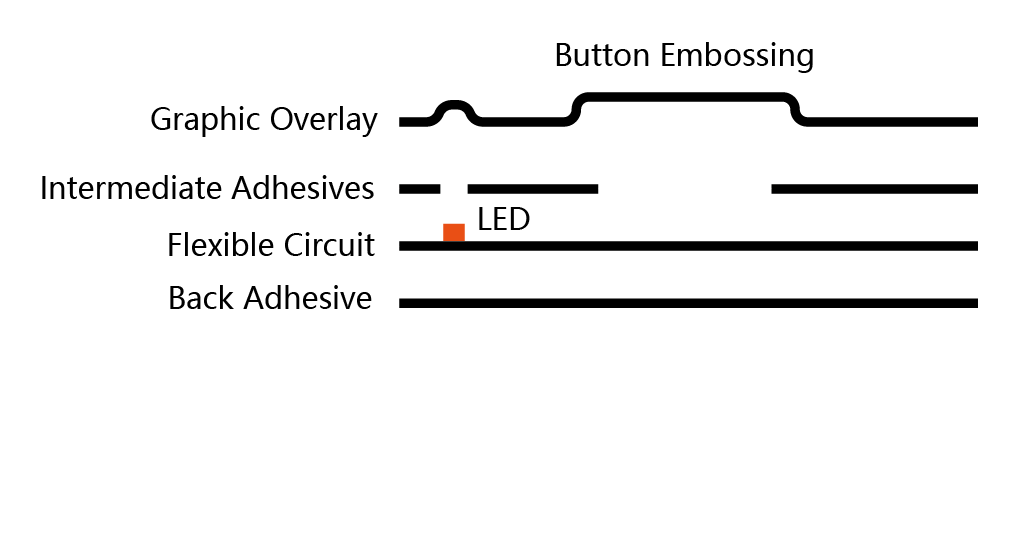

- Spacer Layer

- Function: The spacer layer separates the graphic overlay from the conductive layers below, preventing conduction when the switch is not being activated.

- Structure: The spacer usually has cut-outs at the button locations so that when the graphic overlay is pressed, the underlying conductive layers can make contact and close the circuit.

- Adhesive Layer

- Function: The adhesive layer is used to affix the membrane switch to the surface or frame of the device.

- Characteristics: This layer is typically made from a pressure-sensitive adhesive with strong adhesion that can withstand environmental factors like temperature changes and humidity.

- Metal Dome

- Function: Metal domes provide tactile feedback for a membrane switch, giving a noticeable “click” sensation when a button is pressed.

- Material: These domes are generally made from materials like stainless steel and are available in various sizes and actuation forces.

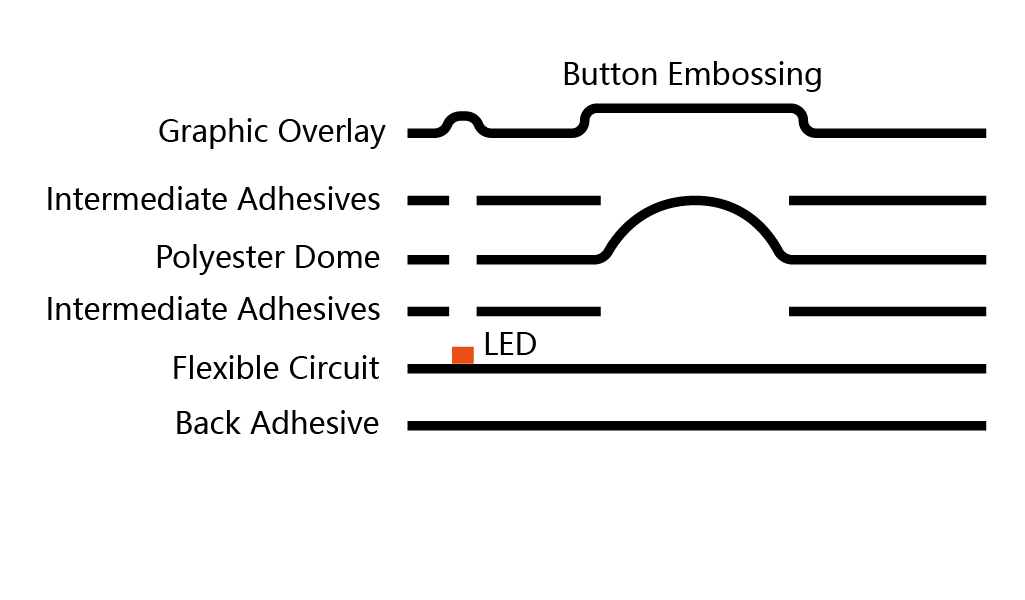

- Flexible Circuit Layer

- Function: The flexible circuit layer contains the circuit of the membrane switch and is responsible for transmitting the user’s operational signals.

- Composition: This layer can be made from etched copper foil, conductive inks, or thin-film conductive materials, designed into specific circuit patterns.

- Rear Adhesive Layer

- Function: Located at the bottom of the flexible circuit, the rear adhesive layer is used to adhere the entire switch assembly to the final product’s surface.

- Characteristics: The adhesive chosen must be compatible with the product’s surface material and capable of maintaining a stable bond over time. For a detailed guide on the use of adhesives in membrane switches, please read the “

Adhesive Solutions and Selection Guide for Double-sided Tapes in Membrane Switches”

- Support Layer

- Function: The support layer provides structural backing to the membrane switch, enhancing its durability and stability.

- Materials: Typically, more rigid materials like plastics or metal sheets are used, chosen in appropriate thicknesses for the application.

- Tail

- Function: Although not mentioned, membrane switches typically include a tail, which is the conductive path that connects the membrane switch to the rest of the electronic device.

- Design: The tail can be a flexible flat cable (FFC) or a wired connector for convenient connection with other electronic components in the device. For membrane switch connectors you can visit the article ” What are the options for Membrane Switch Connectors?“.

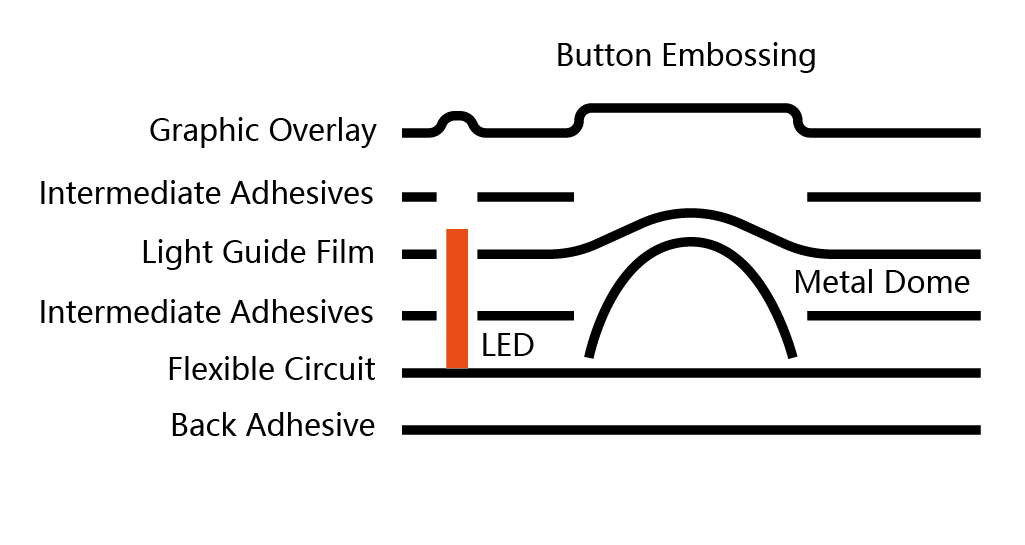

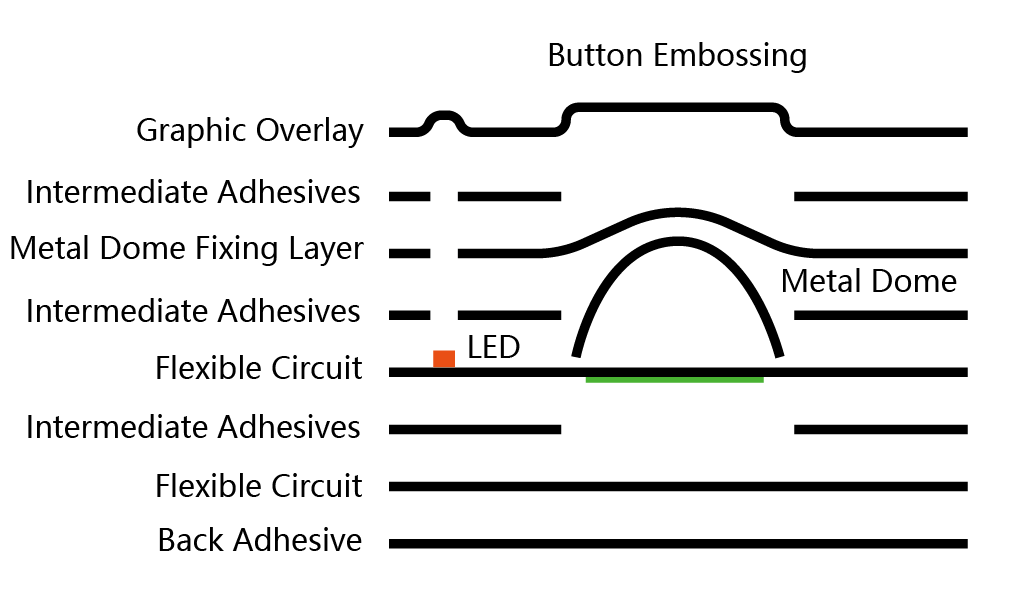

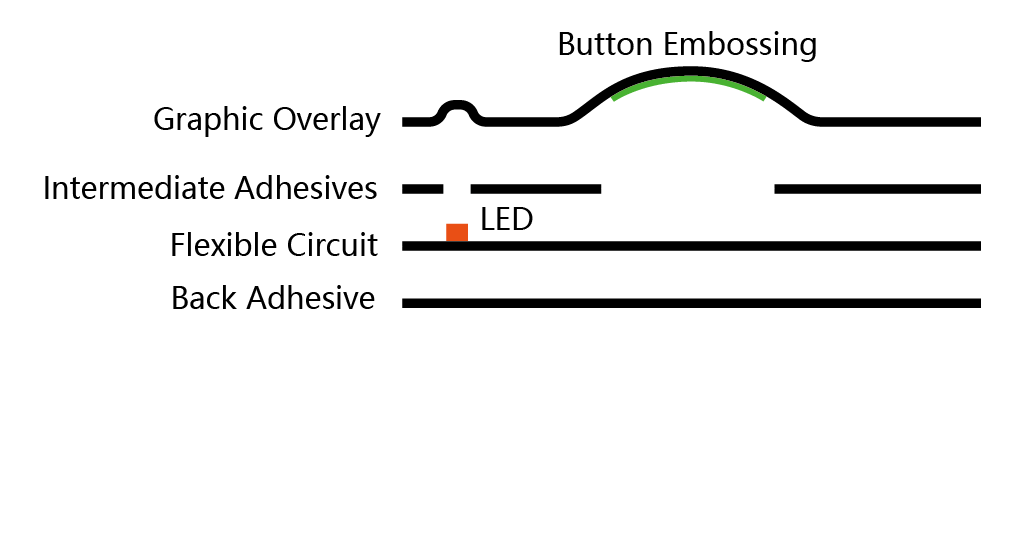

Due to its flexibility, the structure of a membrane switch can be arbitrarily designed according to requirements. The construction of membrane switches has evolved to be very diverse today. In addition to the aforementioned structures, the following image showcases some other common membrane switch structures.

Membrane Switch Solutions and Options

User Interface Design:

• Custom Graphic Interfaces: Interfaces are designed with precision to match customer brand standards, ensuring that colors, graphics, and icons align with the company’s visual identity and meet the aesthetic and functional requirements of the end-user.

• Window Design: Transparent windows specifically crafted for display components enable the visibility of underlying LEDs or LCD screens while protecting the display from external factors. For more on graphic interface products, please visit here.

Silicone Keyboard Membrane Switch Solutions:

- Customization: Silicone keyboards can be designed to various shapes, sizes, colors, and tactile feedback according to application requirements, meeting specific user experience and functional needs.

- Durability: The silicone material has excellent resistance to chemicals, temperature variations, and physical wear, making it an ideal material choice for medical, industrial, and automotive applications.

For more information about silicone keyboard membrane switches please click here, you can also directly consult our engineers.

Environmental Adaptability:

• Water and Dust Resistance: Achieve superior waterproof and dustproof capabilities through sealing technologies and materials like silicone or epoxy resins, suitable for outdoor or industrial settings.

• High Weatherability: Select materials and coatings that withstand UV rays and high temperatures, ensuring that devices maintain performance and appearance even in prolonged outdoor use. For more information on solutions for harsh environments, click here.

Durability and Reliability:

• Enhanced Material Application: Special treatments are applied to materials to enhance durability, such as surfaces resistant to scratches and chemical corrosion.

• Stable Contact Design: Employ durable contact materials, such as metal domes, to ensure consistent response over frequent use. Consult with our engineers for durable and reliable membrane switch solutions by visiting here.

Integrated Solutions:

• LED and Backlight Integration: Incorporate LED indicators or various backlight forms, including traditional LED point sources, LGF backlight systems, or uniform surface light sources such as electroluminescent (EL) and fiber optic backlights.

• Electronic Component Integration: Integrate control circuits, resistors, capacitors, and more to offer an all-in-one control solution. To learn more about backlight membrane switch solutions, visit here, Or you can read the article “How Does an LGF Backlit Membrane Switch Achieve Uniform Light Diffusion?” for further insight. You can also consult directly with our engineers.

Tactile Feedback Options:

• Various Tactile Designs: From the pronounced “click” of a metal dome to the subtle feedback of a polyester dome, to designs without tactile feedback, there’s a solution for every application need.

Surface Treatments and Backlight Options:

• Custom Surface Finishes: Multiple surface treatment options are available, including a variety of textures or high-gloss finishes, meeting both tactile and visual requirements.

• Durable Surface Coatings: Apply coatings that are scratch-resistant and protect against UV/chemical exposure, enhancing the product’s resistance to environmental elements.

Capacitive Switch Solutions:

• Enhanced User Interaction: These are extensively used in home appliances, automotive, and other consumer electronics.

• Simpler Construction and Lower Cost: Capacitive switches require fewer layers (1-3), making them much more cost-effective than membrane switches. For more on capacitive switch products, please visit here, or for a deeper understanding of capacitive switches, view the article here.

Circuit Options:

• Copper Foil Circuits: Ideal for complex circuits and applications with high current demands.

• Silver Paste Circuits: A cost-effective choice for simpler circuit designs.

• Rigid or Flexible Circuit Boards (PCB/FPC): These provide greater mechanical stability and allow for more complex circuit designs. For copper foil circuit products, visit here, or to learn about copper flexible circuits, go to here. Inquiries can also be made directly to our engineers.

Connector Options:

• Flexible Connection Methods: Offer ZIF connectors to reduce insertion force, or choose crimp or solder terminals for a stable connection, along with plug or socket connectors for quick disconnection. Find more information on

membrane switch connectors here.

Shapes and Sizes:

• Custom Sizes: Produced to match the specific dimensions provided by the client, ensuring a perfect fit within the design space.

• Custom Shapes: Capable of being precision-cut into any shape, from simple geometrics to complex contours, adapting to specific design needs. For custom membrane switch design, contact our engineers here.

Special Features:

• Antibacterial Surface: Particularly suited for medical and public spaces, these surfaces inhibit bacterial and microbial growth, maintaining hygiene.

• Multi-Touch Operation: Capable of designing switches that support multi-point touch, suitable for contemporary multifunctional interfaces.

• Integrated Circuits or Components: In addition to traditional membrane switch functions, integrate additional components like LEDs, resistors, and capacitors to expand functionality, simplify assembly and connections, and reduce the need for external parts.

Technical Details

Mechanical properties:

| Type | Specification |

| Actuation Force | 4-16 oz. |

| Switch Travel | .007″ to .035″ |

| Overall Thickness | Varies by materials used in design |

| Size Tolerance | Typically .010″ |

| Tooling | Steel rule dies & hard tools, as well as laser-cutting for prototypes |

| Number of Actuations | Up to 3 million actuations, depending on design |

Environmental performance:

| Type | Specification |

| Humidity | 0 to 98%, no condensation |

| Operating Temperature | -28.9°C (-20°F) to 70°C (+158.0°F) |

| Storage Temperature | -40°C (-40°F) to 70°C (+158.0°F) |

| Salt Fog | 5% salt solution, 48 hours |

Electrical Performance:

| Type | Specification |

| Contact Material | Silver, carbon, gold, or nickel |

| Voltage | 30 volts DC |

| Rated Current/Voltage | 20mA@30 volts DC resistive load |

| Contact Bounce | Less than 20 milliseconds |

| Maximum Switch Power | 1 watt |

| Contact Resistance | Less than 100 ohms (closed loop) |

| Dielectric Strength | 5000V max on polyester material ≥ .0005” |

| Termination | Customer choice |

| Breakdown Voltage to Ground | 1000 volts DC |

| Open Circuit Resistance | 10^6 ohms |

| Capacitance | 20 picofarads |

| Design Configuration | XY matrix, common bus, or custom |

For a comprehensive overview of membrane switch solutions and options, visit here. If you require a membrane switch solution for your challenges, please reach out to us.

WeGlow Industrial offers a range of products including:

- Membrane Switches

- Graphic Overlays (including PC, PET film panels, and acrylic panels)

- Capacitive Touch Switches

- Silicone Keyboard Membrane Switches

- FPC Membrane Switches (flexible copper foil circuits)

- Backlit Membrane Switches

- Sealed & Waterproof Membrane Switches

- Shielded Membrane Switches (ESD, EMI, RFI)

- Pressure Sensors (FSR)

Additionally, WeGlow Industrial also offers PCB rigid membrane switches and rigid support component membrane switch products. You can directly contact our engineers to get these solutions.