FLLOW US:

Silicone Rubber Key Design Guide

· Overview of Silicone Rubber Key

- Basic Structure of Rubber Key.

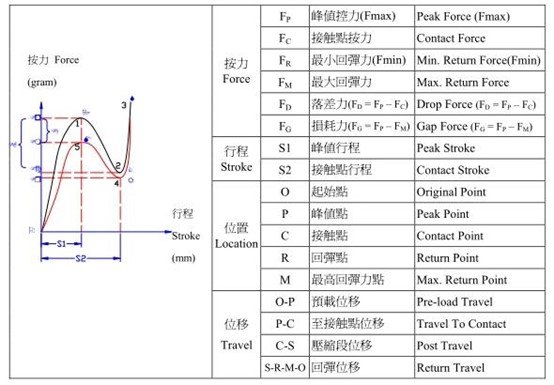

- Force-Travel Curve of Silicone Rubber Key.

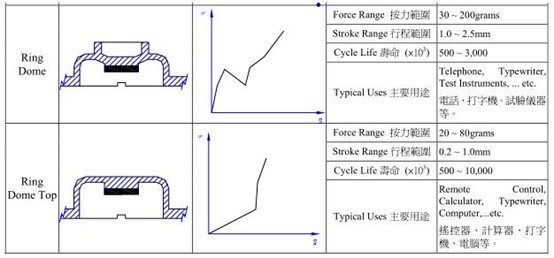

3. Characteristics, Performance, and Applications of Different Structures of Silicone Rubber Key.

· Structural Design of Silicone Rubber Key

- Functional Requirements of Rubber Key Design

- Achieving designated function when pressed.

- Automatic and complete reset after removal of external force.

- Good tactile feel during pressing and resetting, without obstruction or rough sensation; effective when pressing the edge of the key.

- Key Points in Rubber Key Design

3. Technical Requirements

- Actuation force: 130±35 grams.

- Tactile feedback requirements.

- Expected lifespan: 1 x 10^5 cycles minimum.

- Silicone hardness: 50~60°.

- Contact resistance less than 200 ohms.

- Travel = 1.0 (or 1.5) mm.

- Thickness of carbon pill: 1.0mm.

- Contact bounce less than 12 milliseconds.

- Pad color: Optional.

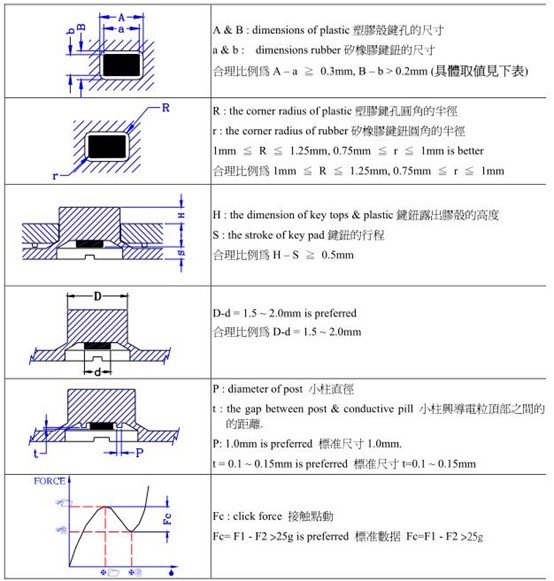

4. Integration of Rubber Key with Plastic Housing

- General design rules.

· Gap Value Recommendation Table

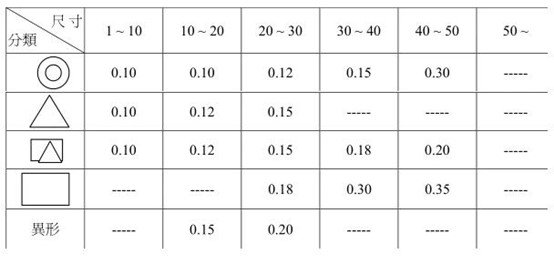

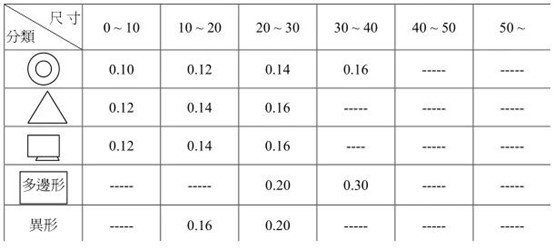

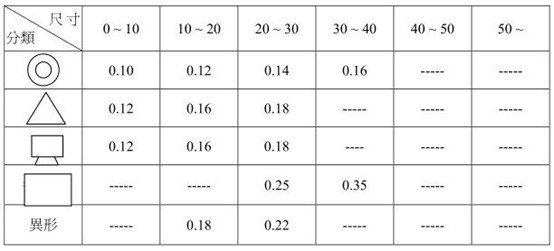

- Influence of silicone rubber key shape, size, and travel distance on design gap values. Simple shapes, smaller sizes, and shorter travel distances generally require smaller gap values, and vice versa. Gap values for integration of Rubber Key with plastic housing (unilateral gaps):

- a. Rubber Key with a travel distance of 1.0mm.

- b. Rubber Key with a travel distance of 1.5mm.

- c. Rubber Key with a travel distance of 2.0mm.

- General dimensional tolerances and precision of the elasticity range.

· Silicone Keyboard with PCB & Membrane Switch Assembly

- Assembly Methods of Rubber Key

- Assembly Methods of Rubber + Key Top (Button)

- Assembly methods for multiple Rubber pieces.

- Assembly method for a single Rubber piece.

· Selection of Rubber Key

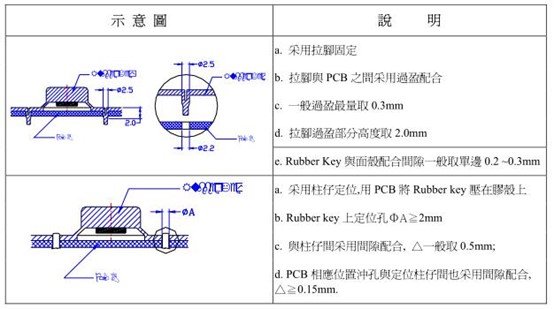

- Considerations when selecting Rubber Key: Travel, rebound force, and preload (height of the compressed part of Rubber should be greater than the distance between the key and PCB to prevent shaking in the normal state, typically 0.2mm). Examples of typical selections.

· Auxiliary Design Parts of Rubber Key

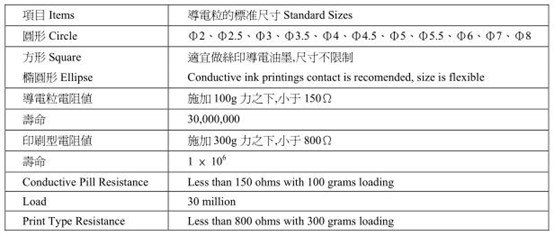

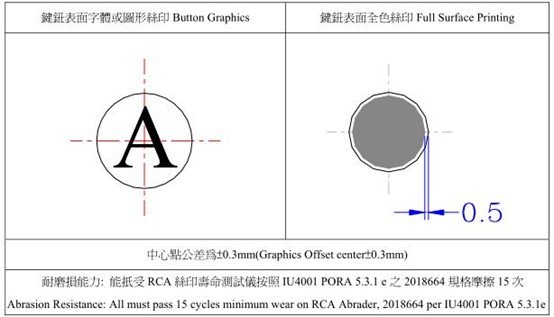

- General design specifications for conductive particles.

- General concepts of silk screen printing.

· Performance and Testing of Rubber Key

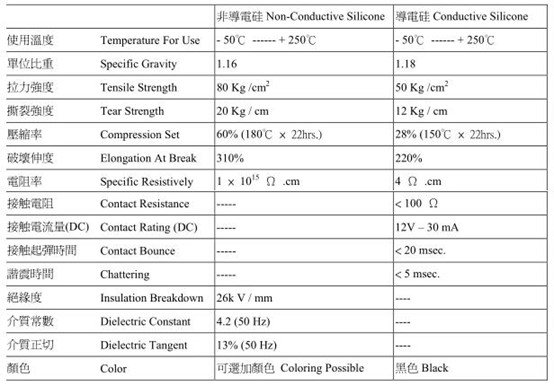

- Mechanical and electrical properties of silicone.

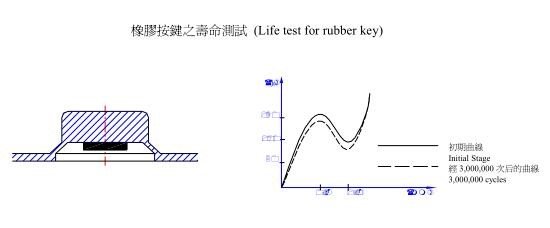

- Life test of silicone rubber keys.

· DA Design Review Content

- Check if the structure’s corresponding performance and usage match the design requirements.

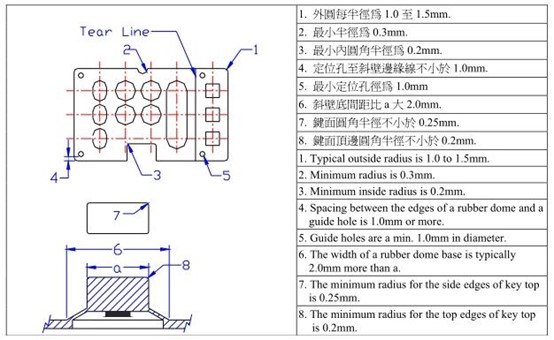

- Specific structural requirements:

- Distance from the positioning hole to the edge of the sloping wall not less than 1.0mm.

- Positioning hole size not less than 1mm.

- Key surface radius not less than 0.25mm.

- Requirements for the gap between plastic housing and Rubber Key.

- Assembly method with PCB and preload of Rubber (generally 0.2mm).

- Silk screen test reference for Rubber Key surface: QAD-TEI-011.

- Life test of Rubber Key, meeting the corresponding lifespan requirements.

You can read “What are Silicone Rubber Keypads?” for more information about silicone membrane switches.

Visit our homepage for more product information and solutions.